EVERYTHING

UNDER ONE ROOF

SS Laser Cut& 3D Printing is known for quality services, exceptional efficiency and the highest level of professionalism. No matter what services you are looking for, we guarantee to not only meet, but exceed your expect ations. Our team is up for every job, managing projects with the skill and experience our clients expect us to deliver.

Industrial 3d printing services, SS Laser Cut & 3D Printing offers professional 3d printing technology. We can produce high quality parts in multi materials and finishes with lead time. We can turn the most complex ideas in to physical item within a short span of time. Now you can even conveniently order 3d prined parts online and have them delivered at your doorstep.

We are working in the market since last 40 years. We have two more industries In Indore Our parent units (SURESH Engineering Works & JJ INDUSTREIS) are engaged in the business of manufacturing drip irrigation pipe machines. We have an.....

experienced technical team and service engineers to provide the best service to our customers. So far, we have sold 1500+ Machines all over India.

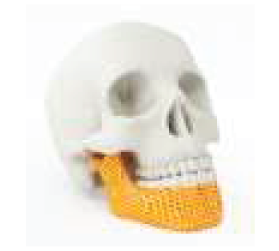

We're the third gener ation in this business and we're here to set a new benchmark. Our products shall make businesses an easy go. Our products include: 3D prototyping, machine design parts in 3D printing and medical equipments. We're looking forward to developing a huge customer base with maximum satisfaction levels. Our domestic market has an all-India coverage and we're all set to enter the in ternational market soon.

To make all the different additive manufacturing technologies and medical trchnologies services available to every individual and every organiz ation under one roof. To serve our customers with clear, concise communication & in formation & high-quality products along with afriendly customer experience.

Plasma cutting is useful in today's time, in every big industry and every small industry must do the work quickly and well with finishing we are now here to work with every industry to do your work fast and easy. Every industry is growing extremely fast in the present time, however, the way of working of these industries is also changing. A plasma cutting high-precision cut accuracy of ±0.01 to 0.05 mm. In plasma cutting we are giving our best service to the customer’s. we are also working with materials and without materials also.

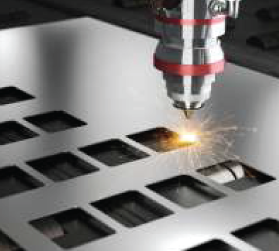

Laser cutting is the go-to technology to perform such jobs in the industry because of its many advantages over other methods. At the same time. The precision levels and edge quality achieved with laser cutting machines are better than traditional cutting methods. Laser Cutting presents certain advantages over plasma cutting as this process is more precise and uses less energy when cutting steel and aluminium sheets. Laser cutting is a manufacturing process which can eliminate the need for machining on many engineering jobs, enabling you to save money on manufacturing costs. An accuracy of +/-0.1 mm gives an opportunity to achieve high precision without any after-treatment. In most cases, such a high standard means that no added tolerances are required.

Laser Engraving (or Laser Etching) is a Subtractive Manufacturing method, that uses a laser beam to change the surface of an object. This process is mostly used to create https://sslazer3d.com/front_assets/images on the material, that may be seen at eye level. ... It is using the laser for marking the surface of an item.

1. A design is a plan or specification for the construction of an object or system or for the implementation of an activity or process, or the result of that plan or specification in the form of a prototype, product, or process. The verb to design expresses the process of developing a design.

1. A design is a plan or specification for the construction of an object or system or for the implementation of an activity or process, or the result of that plan or specification in the form of a prototype, product, or process. The verb to design expresses the process of developing a design.

2. A prototype is an early sample, model or release of a product created to test a concept or process. Typically, a prototype is used to evaluate a new design to improve the accuracy of analysts and system users. ... Prototypes are a crucial part of the design process and a practice used in all design disciplines.

3. 3D Quality Control is the evaluation of industrially manufactured parts in detailed measures by using 3D Quality Control Systems. In the process, the object's data is displayed and analysed in 3D. Especially during pre- production stage of the manufacturing life cycle, this method can effectively optimize the final product.

Address:

Office add:- 14 'B' Kalyan Vishranti Grah , Near Railway Station, Jhabhua Tower Road,Indore - 452001 (M.P.)

Contact : 0731-4960565,

+91 9752510021, +91 9752030021

Factory add:-

153-A, Sector 'F', Industrial Area, San wer Road, Indore - 452015 (M.P.) Contact:+91 91311-72872, +91 99770-04632

© Copyright 2021 | All Rights Reserved